Split rim wheels were used over 30 years on larger trucks with inner tubes. They were the only method of keeping the tube within the tire under air pressure and to allow for easy removal of the tire from the rim by tire repair shops and individuals in home garages.

An over view of tire removal was to remove the air pressure, push the top bead of the tire down to release pressure from the small circular lock ring. This ring must be rotated several degrees until it can easily be removed from the wheel. This allowed easy access to the tire and tube to be removed.

The big danger is when a more unskilled person replaces the lock ring without fully turning it to its correct position. Unfortunately, the tube will still take in air pressure when the lock ring is not fully secured into the proper position. It is then when what happens that has given split rim wheels such a bad reputation of permanently damaging a tire repair person, so many did not live to see the next day!

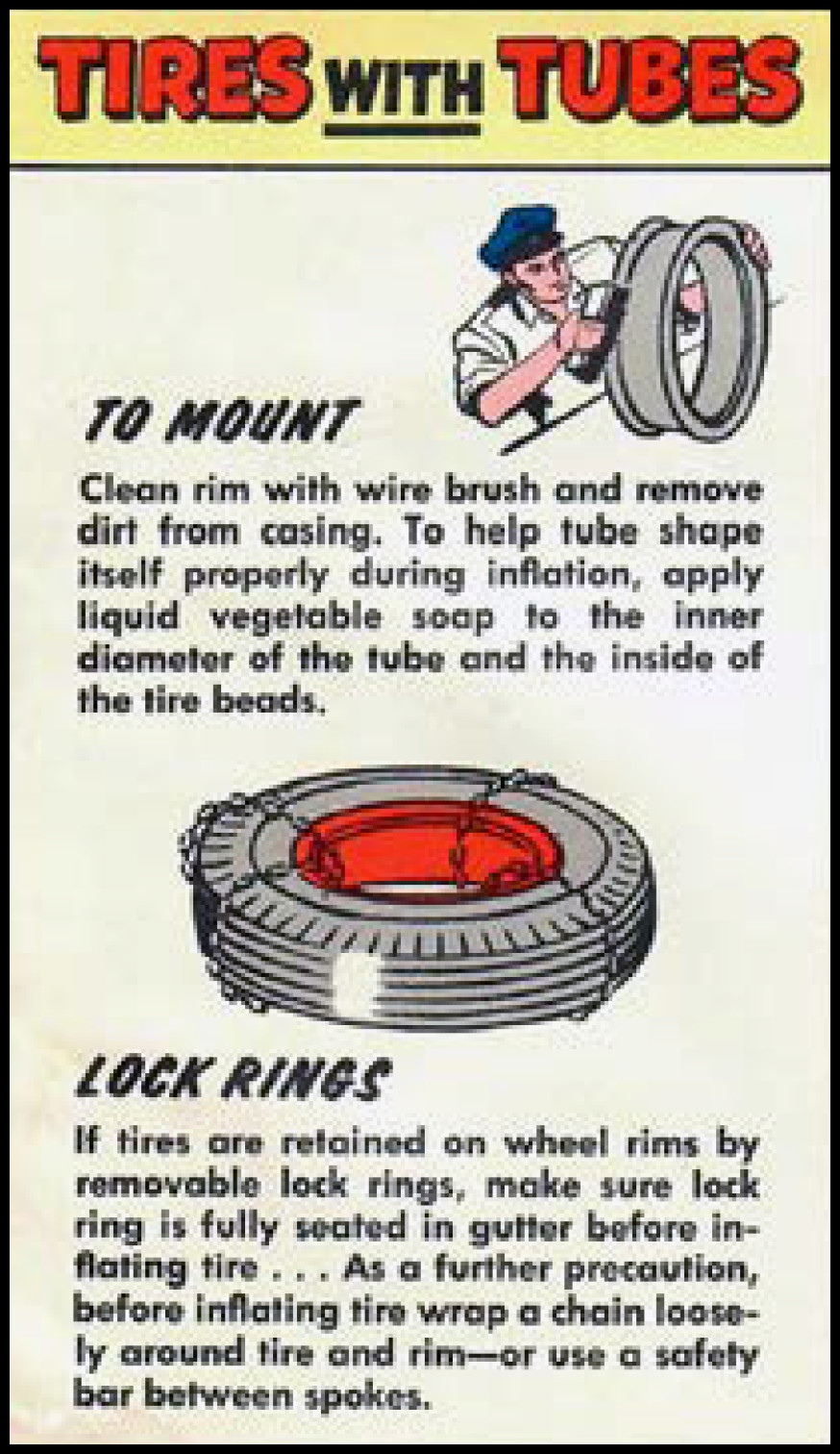

General Motors was well aware of dangers of not completely turning the lock ring into the required position. This recommendation applies today just as it did in the early years.

The following shows a diagram from a 1959 GMC operation manual. To prevent a major accident, simply place 4 chains around the tire and rim and fastener. In case the worst happens while adding air, the lock ring stays within the retainer chains! (How many small shops and farm owners took this precaution?)