Before the modern Positive Crankcase Ventilating System (PCV) most automotive engines breathed externally and removed their excess products of combustion into the atmosphere. It was a standard of the industry!

The lower end of the engine (below the piston rings) had an attached draft tube that extended outside and below the block. It released blow-by from worn piston rings and other pollutants created from the crankshaft turning in hot motor oil.

The upper end of the overhead valve engine (above the piston rings) also must breathe. On early Chevrolet and GMC inline six cylinder engines, the venting is usually in the valve cover through factory slots. When their add-oil cap exists on this cover, it seals tight. It does no breathing.

On 1955-62 Chevrolet 235 six cylinders, the valve cover slots were illuminated. It is assumed badly worn engines at high RPM leaked oil at these slots. The venting requirement was now moved to the oil cap. These redesigned caps have two features. They cover the add oil hole and vent the upper end of the engine. Their disadvantage is their internal filter can clog with oil vapors and dirt from a badly worn engine. This type venting cap must be kept clean!

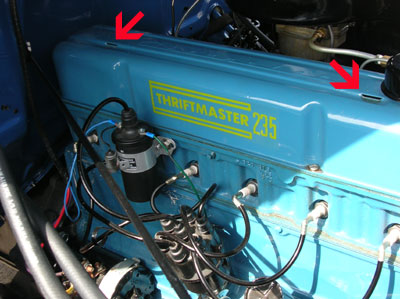

The following photos show venting methods on early Chevrolet and GMC engines. Note the oil and breathing cap on the later six cylinder Chevrolet engines.

1937 through 1953 216 sealed oil cap (above)

216 valve cover one of several slotted vent (above)

1954 Chevrolet Vents (above)

1955-1962 non vented cover (above)

1955-1962 vented oil cap (above)

1963-1972... 230 and 250 with PVC system (above)

Once again the oil and cap is sealed.

gГјnstige online apotheke

versandapotheke versandkostenfrei

online apotheke versandkostenfrei

online-apotheken

online-apotheken

versandapotheke

internet apotheke

online apotheke gГјnstig

versandapotheke versandkostenfrei

online apotheke versandkostenfrei

online apotheke gГјnstig

online-apotheken

online apotheke preisvergleich

online-apotheken

п»їonline apotheke

online apotheke versandkostenfrei

online apotheke preisvergleich

п»їonline apotheke

versandapotheke versandkostenfrei

online apotheke versandkostenfrei

online apotheke versandkostenfrei

п»їonline apotheke

versandapotheke versandkostenfrei

online apotheke preisvergleich

internet apotheke